Reinventing Safety Training For Manufacturing

The manufacturing industry is associated with high risks. From heavy machinery and chemical exposure to repetitive motions and electrical hazards, employees face daily challenges that require strict safety protocols.

Traditional in-person training has long been the norm, but the shift to digital solutions, accelerated by remote work trends and the need for scalable learning, has made online safety training essential. However, transitioning to virtual training isn’t as simple as uploading a PowerPoint deck. It requires strategic planning, engaging content, and powerful training software. Let’s explore how to design and deliver online employee safety training in manufacturing environments.

Step 1: Conduct A Thorough Needs Assessment

Before building any training program, you need to understand the unique risks and requirements of your workforce. A thorough needs assessment involves collaborating with floor managers, safety officers, and employees to identify knowledge gaps. For example, if you have introduced automated machinery recently, workers might lack knowledge about lockout/tagout procedures.

Review past incident reports, audit findings, and regulatory standards, like OSHA guidelines, to identify critical areas. Surveys and focus groups can also reveal employee concerns, such as language barriers or confusion about emergency exits, that your training should address. This foundational step ensures that your program isn’t just a checkbox exercise, but a targeted solution to real-world issues.

Step 2: Set Clear, Actionable Learning Objectives

Vague goals like “understand safety protocols” won’t cut it. Effective objectives are always specific and measurable, such as, “By the end of this module, workers will be able to identify chemical hazards in their workspace and demonstrate proper PPE usage.” These objectives guide content creation and help employees retain the knowledge of what’s expected of them. They also align with compliance requirements so your training will always meet legal standards.

Step 3: Prepare Engaging Learning Content

The age-old dilemma in workplace safety training is whether to buy generic off-the-shelf courses or create bespoke content that resonates with your team. Pre-made courses might save time upfront, but they often lack relevance to your organization’s specific hazards, workflows, or culture. Employees are quick to disengage when training feels irrelevant to their daily routines. Worse still, purchased content can’t be easily updated to reflect new machinery, protocols, or regulations, leaving gaps in compliance.

For manufacturers, the solution lies in developing customized safety training that mirrors your unique environment. This is where iSpring Suite, a powerful yet intuitive authoring tool, comes into play. Integrated with PowerPoint, it allows even non-technical teams to design professional, interactive courses quickly. With pre-built templates and a library of realistic workplace characters and settings, iSpring Suite turns safety training into an immersive experience rather than a compliance chore.

Here’s what you can create with iSpring Suite.

Interactive Online Courses

Transform static safety protocols into engaging learning journeys. For example, build a fire safety course in which employees click on images to identify hazards in a virtual factory, lay out evacuation steps, or extinguish simulated fires using the correct equipment. Embed diagrams of your organization’s evacuation routes or videos of emergency drills that are conducted onsite.

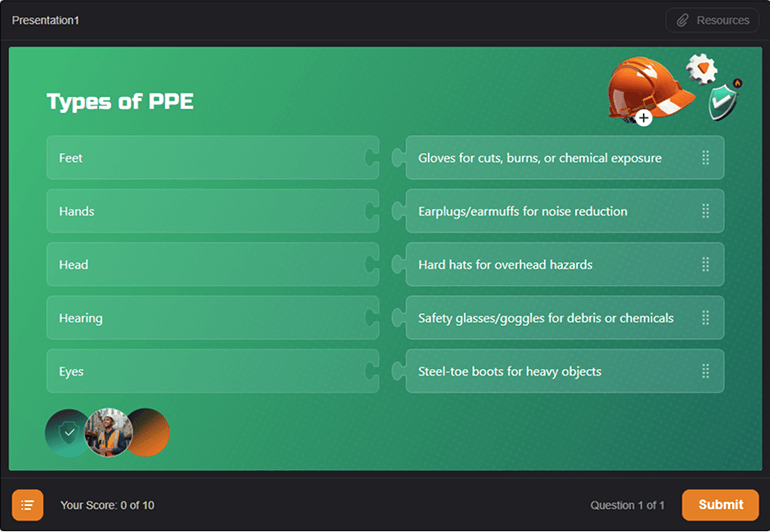

To ensure that employees retain critical information, add interactive quizzes to courses. For instance, use multiple-choice questions to test hazard recognition and drag-and-drop exercises to match PPE to specific risks. Add feedback to clarify mistakes and reinforce correct procedures.

Training Videos

Use instructional videos to demonstrate safety protocols:

- Talking-head videos – Record your safety officer explaining updated PPE guidelines or emergency shutdown processes.

- Screencasts – Show how to log incidents in your facility’s safety management software.

- Picture-in-picture demos – Film a trainer inspecting machinery while highlighting risks.

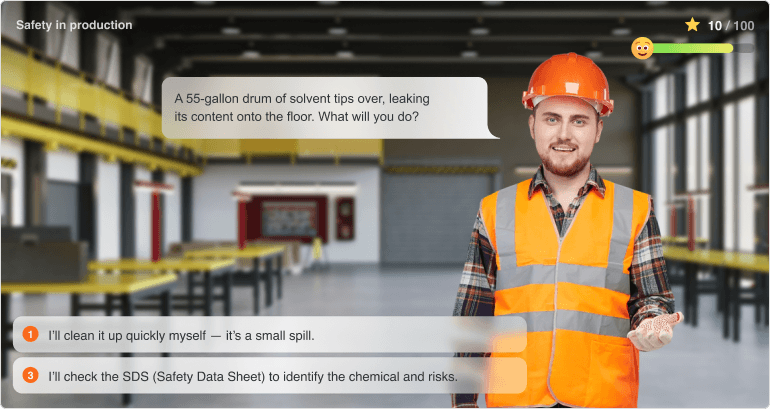

Real-World Simulations

Prepare employees for high-risk scenarios through branching role-plays. For example, with iSpring Suite, you can easily create a simulation in which a worker must safely handle a chemical spill: each decision (e.g., choosing PPE, containing the spill, reporting the incident) leads to consequences, with instant feedback.

Step 4: Deliver And Automate Training

Creating effective safety content is only half the battle. Ensuring it reaches the right employees at the right time and in the right format is equally important. This is where you will need a Learning Management System (LMS). The iSpring Learn LMS is designed to integrate with iSpring Suite seamlessly, offering manufacturers a unified solution for deploying, managing, and automating safety training.

The LMS has all the functionalities needed to handle the demands of manufacturing companies. Its intuitive interface allows managers to organize courses by department (e.g., warehouse, assembly line, maintenance) or risk type (e.g., chemical handling, machinery safety) and assign them to employees with ease. But the real power lies in its automation capabilities, which help eliminate administrative bottlenecks.

With iSpring Learn, you can:

- Auto-enroll employees by role – Assign specific courses to workers based on their job functions. For example, new hires in the welding department can automatically receive training on arc flash safety and PPE usage.

- Schedule recurring training – Set rules to trigger refresher courses annually or after incidents.

- Deadline reminders – Reduce compliance risks by providing automatic notifications for upcoming due dates.

- Certification management – Issue certificates automatically upon course completion and renew them when retraining is required.

Step 5: Measure Learner Results

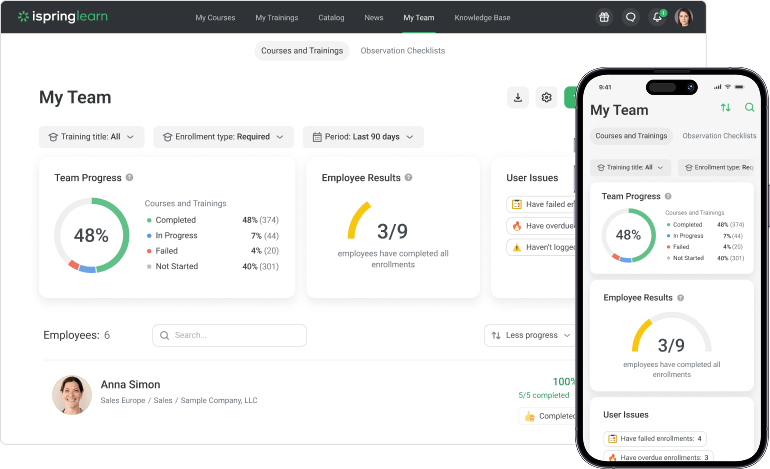

Training’s true value lies not just in completion rates but in its tangible impact on workplace safety. Platforms like iSpring Learn provide powerful analytics that help turn raw data into actionable insights. After employees complete safety courses, use LMS reports to track metrics like completion rates, quiz scores, and time spent per module, and assess pass/fail details.

For example, if a report reveals that 30% of employees scored poorly on a specific module, you can quickly identify gaps and assign refresher training. Drill deeper into individual performance to pinpoint employees who may need mentorship, or analyze department-wide trends to spot recurring issues. Export compliance records for audits or visualize trends over time to prove ROI to stakeholders.

Step 6: Refine And Enhance Training

Even the most well-designed safety training program isn’t static—it evolves together with your workforce, equipment, and regulations. To ensure your training stays relevant and effective, embed feedback loops into the process.

Gather direct feedback from employees after training through quick surveys. Ask targeted questions like, “Did the simulations reflect real workplace scenarios?” or “What key manufacturing safety topics do you feel need more clarity?” Pair this with insights from managers and safety officers—observe whether employees apply protocols correctly on the floor and if incident reports decline. This will help you make your training even more effective.

Build A Culture Of Safety, Not Just Compliance

Online safety training isn’t just about avoiding fines—it’s about empowering employees to protect themselves and their coworkers. By combining thorough needs assessments, developing engaging interactive content, and using robust LMS analytics, manufacturers can create training programs that resonate with workers and drive lasting behavioral change. The result? Fewer accidents, higher morale, and a workplace where safety is a fundamental part of everyday operations.

iSpring Learn

iSpring Learn is a fast LMS for your mission-critical project. Launch your eLearning in one day with a minimum of fuss. Just upload your training materials, invite employees, and keep track of their results.