When it comes to automation technology, the list of greenhouse grower needs today are multiple, including automation to minimize repetitive tasks (free up labor for other needs) and make it easier to keep good people. Growers are looking for machines that can use artificial intelligence (AI) and computer vision to make repetitive decisions, and automation to improve product consistency (or sort with objectivity). Operations need increased output with the same amount of people due to labor shortages and increased demand for products, and automation for detecting diseases, insects/, and abiotic stress effects.

Keep reading to learn more about how greenhouse technology companies are responding to these needs with new product offerings.

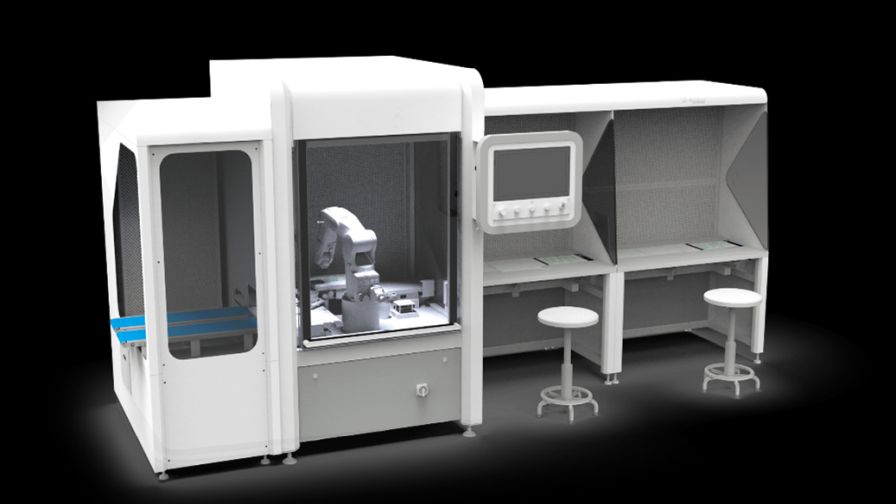

Viscon TC Plantr

Viscon

TC Plantr is Viscon’s newest answer to address labor shortages and increased starter plant demands. This machine combines robotics, computer vision, software, and AI to increase starter plant production without increasing labor costs. Viscon is combining this technology with other machines for greater autonomy.

Viscon has also released the Roulette XL Seeder, with features such as high precision, flexibility, and ease of maintenance. With a capacity of 800 to 1,000 trays per hour, the built-in software offers the option to program the seeder and easily recall the settings via a touchscreen monitor.

Bold Robotics Pot Cover Labeler

Bold Robotics

Bold Robotics’ pot cover labeler has gained traction over the last few years among growers, says Bill VandenOever of Bold Robotics, because of how it has streamlined the labeling process. It is able to label on demand and drastically reduce the labor needed to perform this task.

“The labeler enables growers to improve their packaging process by reducing the amount of labor required to apply labels to preformed pot covers,” he says. “A job that was originally performed by six or more people can now be done by one machine operator who can run multiple machines, or work on other tasks while using this machine.”

The labeler also reduces errors by streamlining the data to pot cover process by printing on demand rather than having to pre-print and then apply.

“It creates a better work environment since the boring task of labeling is automated, creating higher skilled labor opportunities and allowing for resource availability for more value-added tasks, which creates a more attractive workplace,” says VandenOever.

AdeptAg Single Rail Ground Boom

AdeptAg

Single Rail Ground Booms from AdeptAg optimize outdoor bay irrigation by maximizing space and efficiency. Designed to span the full width of outdoor bays, they are supported by a ground rail, minimizing the pathway and increasing growing space. These booms accommodate multiple irrigation hoses for high-water consumption applications and include an integrated maintenance platform.

Constructed with hot dip galvanized materials, they ensure durability. Features include an integrated cable carrier for efficient hose and cable management and an adjustable height irrigation boom spray bar. Compatible with PR1 and PR2 controllers, they offer seamless system integration.

Erfgoed Ultrafiltration Water System

ErfGoed

Earlier this year, ErfGoed introduced a newer technology at The Plant Company in Stuarts Draft, VA, where it installed an ErfGoed WaterSystem, including an Ultrafiltration unit called Kathari.

“Ultrafiltration physically removes pathogens from water using membranes that block viruses, bacteria, and fungi while allowing nutrients to pass through to be reused,” says Jack Ford, North American Sales Manager at ErfGoed. “Ultrafiltration is a proven and globally applied technique that guarantees stable water quality and quantity.”

Ford says the Kathari system achieves high reductions of viruses and bacteria, uses little energy, and requires minimal maintenance, keeping operational costs low. It is suitable for various water sources, such as dirty drain water, closed-loop systems, ponds, and large surface water.

“It can be integrated with any horticultural environmental and watering control systems,” Ford says. “Automatic integrity tests ensure the proper functioning of the membranes, thereby safeguarding crops.”